In a world powered by electricity, few technologies are as fundamental yet as often overlooked as the turbine generator. These marvels of engineering are the silent giants behind our power grids, transforming raw kinetic energy from wind, water, or steam into the reliable electrical power that lights our homes, fuels our industries, and connects our digital lives. Far from being simple machines, turbine generators are sophisticated systems that harness the very laws of physics to meet humanity's insatiable energy demands.

At its core, a turbine generator is a device that orchestrates a delicate dance between motion and magnetism to produce electricity. It doesn't create energy out of nothing, but rather converts mechanical energy—often derived from the powerful flow of a fluid—into a usable electrical current. Understanding this intricate process reveals the ingenuity behind our modern power infrastructure and how we continuously push the boundaries of efficiency and reliability.

The Heartbeat of Power: Understanding the Generator Principle

Before we delve into the full turbine generator system, it's essential to grasp the fundamental principle of a generator. Imagine a device that takes any form of mechanical energy – be it the force of falling water, the pressure of high-temperature steam, or the relentless push of wind – and meticulously transforms it into electricity. This conversion is the generator's primary role, acting as the crucial bridge between a moving force and an electrical current.

This process relies heavily on the principles of electromagnetism, particularly Faraday's Law of Induction, a discovery from the 1800s that underpins most of our electrical world. To truly appreciate the elegance of this conversion and explore operational principles and components of these vital machines, we must first understand the journey from a simple spin to a robust flow of electrons.

From Motion to Electrons: How a Generator Works

The journey of generating electricity begins with rotational motion, typically imparted by an external mechanical force. Here’s a simplified breakdown:

- Mechanical Input: An external source, such as wind turbine blades, steam turbine blades, or a gas engine, delivers mechanical energy to a spinning rotor. This rotor is affixed to a central turbine shaft.

- Internal Rotation: As the turbine shaft rotates, it drives internal machine parts, most notably a coil of copper wire known as the armature. This armature spins at the same speed as the shaft.

- Magnetic Field Interaction: Within the generator casing, two powerful polar field magnets establish a constant magnetic field. The rotor, shaft, and armature are designed to move within this field.

- Electricity Generation: When the copper armature coil rotates through this stationary magnetic field, it induces an electrical current within the wire. The faster the armature spins through the magnetic field, the stronger the electrical current produced.

- Electricity Extraction: The resulting electricity, typically as alternating current (AC) due to the opposing directions of the coil ends' movement through the field, is then safely channeled out of the generator and prepared for distribution.

Powering Our World: Diverse Types of Turbine Generators

Turbine generators don't just exist as a singular design; they are highly specialized machines, each tailored to convert specific types of fluid energy into mechanical work, which is then fed into the electrical generator. These systems are central to nearly every thermal, nuclear, and industrial power plant, forming the backbone of global energy production.

Whether it's the sheer power of steam, the intense heat of combustion gases, or the relentless force of water, each fluid demands a unique turbine design. By delving into these specialized approaches, we can better understand how these systems are optimized for different environments and energy sources. To learn more about how these incredible machines are categorized and applied, you can discover the various Types & Classification of Turbine generators.

Steam Turbine Generators

These are workhorses in utility and process plants, renowned for their scalability and ability to leverage diverse steam sources—from coal and natural gas to biomass, waste heat, and nuclear fission. High-pressure steam expands across multiple stages of blading, meticulously designed to spin the rotor with immense force. Continuous advancements in blade profiles, seal technologies, and control systems, along with their integration into cogeneration setups, consistently boost their efficiency and output.

Gas Turbine Generators

Gas turbine generators operate through a fascinating thermodynamic cycle: they compress air, mix it with fuel, ignite the mixture, and then expand the resulting high-temperature gas through turbine stages. This expansion drives the work output. Their efficiency is critically dependent on factors like firing temperature, the compressor's pressure ratio, and meticulous maintenance of the hot section components. In advanced combined cycle plants, the exhaust heat from the gas turbine is ingeniously used to generate steam for an additional steam turbine, dramatically increasing overall net efficiency.

Hydro Turbine Generators

Harnessing the ancient power of moving water, hydro turbine generators convert hydraulic head (the difference in water levels) into rotational power. Depending on the site's specific conditions—such as water volume and fall height—engineers select from designs like Francis, Kaplan, or Pelton turbines. These systems boast low variable operating costs and are invaluable for providing peaking power, frequency support for the grid, and other critical ancillary services. Their efficiency is finely tuned through runner geometry, precise wicket gate control, cavitation management, and advanced digital governors.

Where Power Comes to Life: Applications and Impact

The presence of turbine generators is ubiquitous, underpinning nearly every facet of our modern electrified existence. From the vast landscapes of utility-scale power plants to the specialized needs of industrial facilities, these systems are indispensable. They are the engines driving our progress, ensuring that hospitals, homes, data centers, and factories all have the power they need, when they need it.

Their strategic deployment across various sectors highlights their adaptability and critical role in diverse energy ecosystems. Whether it's ensuring grid stability or providing independent power for remote operations, turbine generators are at the forefront. To gain a deeper understanding of their real-world significance and how they are integrated into various economic sectors, we invite you to explore Applications & Industry Use Cases for these powerful machines.

Maximizing Output: Engineering for Efficiency and Reliability

Achieving peak performance and unwavering reliability from turbine generators is a continuous pursuit of engineering excellence. Maximizing the output isn't just about the initial design; it involves a meticulous focus on operational strategies and advanced technological integration throughout the machine's lifecycle. Every component, every process, and every operational decision contributes to the overall effectiveness of these complex systems.

Improving efficiency and reliability means pushing the boundaries of what these machines can deliver, while ensuring they remain operational for decades. Engineers leverage a combination of thermodynamic principles, aerodynamic refinements, rigorous operational discipline, and cutting-edge digital insights to continually enhance performance. For those interested in the granular details of how these systems are perfected, Efficiency, Performance & Optimization offers a deep dive into these critical strategies.

Key levers for achieving this optimization include:

- Thermodynamics: Optimizing the expansion ratio of the working fluid and minimizing back pressure or exhaust losses are crucial. This involves better steam conditions, superior condenser performance, and finely tuned control schedules.

- Aerodynamics and Hydraulics: Utilizing advanced blade profiles, ensuring tighter tip clearances, and maintaining smooth surfaces all contribute to reducing profile and secondary losses within the turbine.

- Heat Rate Discipline: Rigorous Operations and Maintenance (O&M) practices are essential to manage fouling, prevent leakage, ensure proper alignment, and control parasitic loads. These efforts are often supported by quantified performance testing to ensure continuous improvement.

- Digital Monitoring: Modern turbine generators benefit immensely from digital monitoring systems that track vibration, temperature, and overall performance. These analytics enable condition-based maintenance and targeted overhauls, effectively preventing costly and disruptive unplanned outages.

Sustaining the Lifeline: Maintenance and Strategic Management

The long-term viability and consistent performance of turbine generators hinge on thoughtful selection and comprehensive asset management strategies. Choosing the right turbine generator for a specific application requires careful consideration of its duty cycle, the availability of fuel or steam, unique grid requirements, ambient environmental conditions, and water limitations. Just as critical is defining a robust, long-term maintenance strategy from the outset.

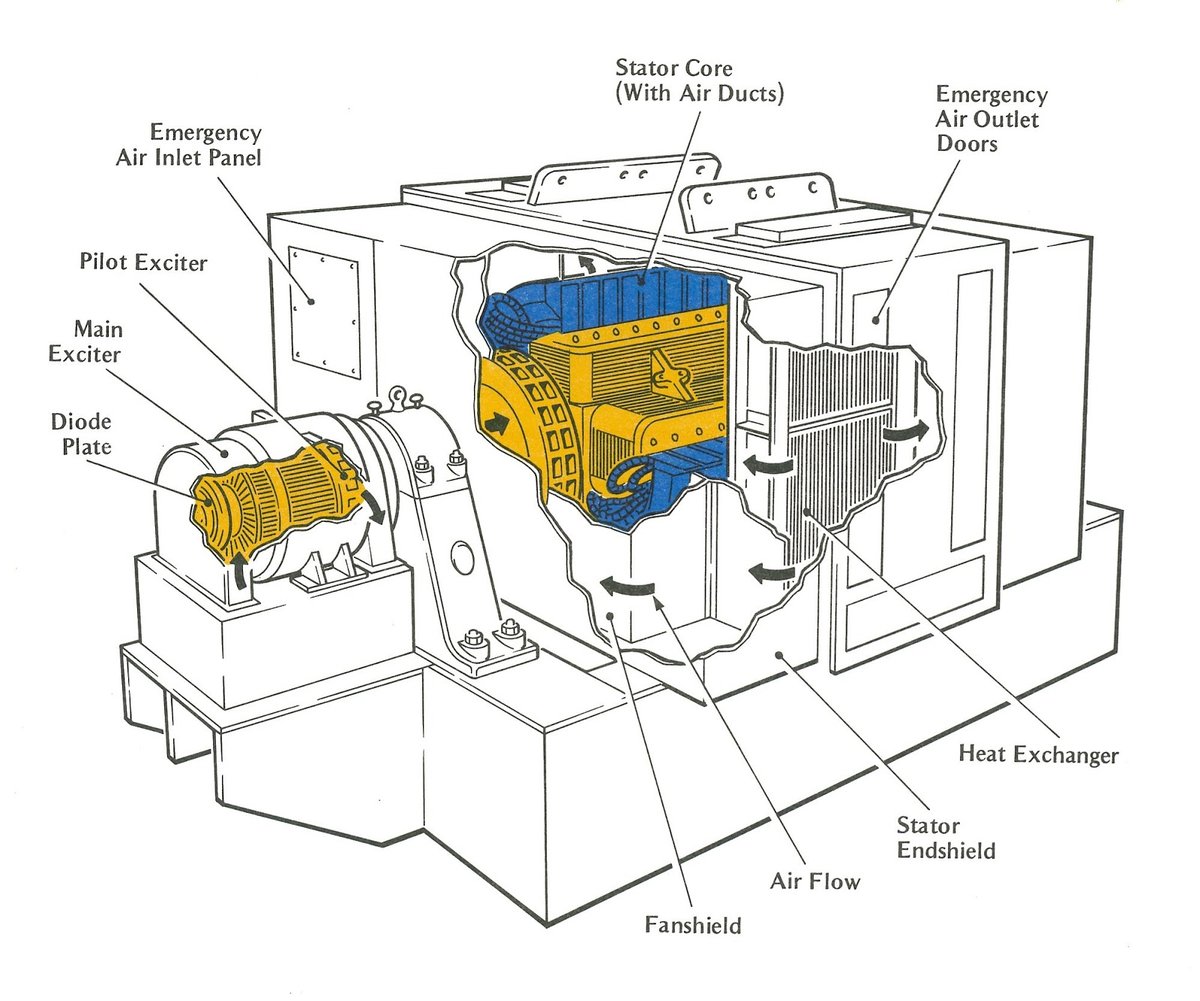

Ensuring consistent rated performance also depends on properly sizing all auxiliaries, excitation systems, and protection systems. Over their operational lifespan, these machines require diligent care to prevent downtime and costly repairs. Understanding best practices for their upkeep is paramount. To gain insights into ensuring the longevity and optimal function of these critical assets, Maintenance, Troubleshooting & Asset Management provides comprehensive guidance.

Digital monitoring, as mentioned earlier, is revolutionizing maintenance by shifting from reactive repairs to predictive interventions. By analyzing real-time data on vibration, temperature, and performance, operators can anticipate potential issues, schedule maintenance precisely when needed, and avoid unexpected failures that can halt power generation. This proactive approach significantly extends asset life and enhances overall system reliability.

The Future of Power, Driven by Movement

Turbine generators stand as a testament to human ingenuity, translating the fundamental forces of nature into the lifeblood of our modern world: electricity. As we look towards a future demanding more sustainable and reliable energy solutions, the evolution of these machines will continue to be pivotal. From enhancing their efficiency through advanced materials and digital twins to integrating them seamlessly with evolving smart grids, the journey of the turbine generator is far from over.

Their foundational role in our energy landscape ensures that continued innovation in their design, operation, and maintenance will empower generations to come. The delicate balance of movement and magnetism will persist as a cornerstone of our electrified existence, driving progress one spin at a time.